Welding control - TDiM

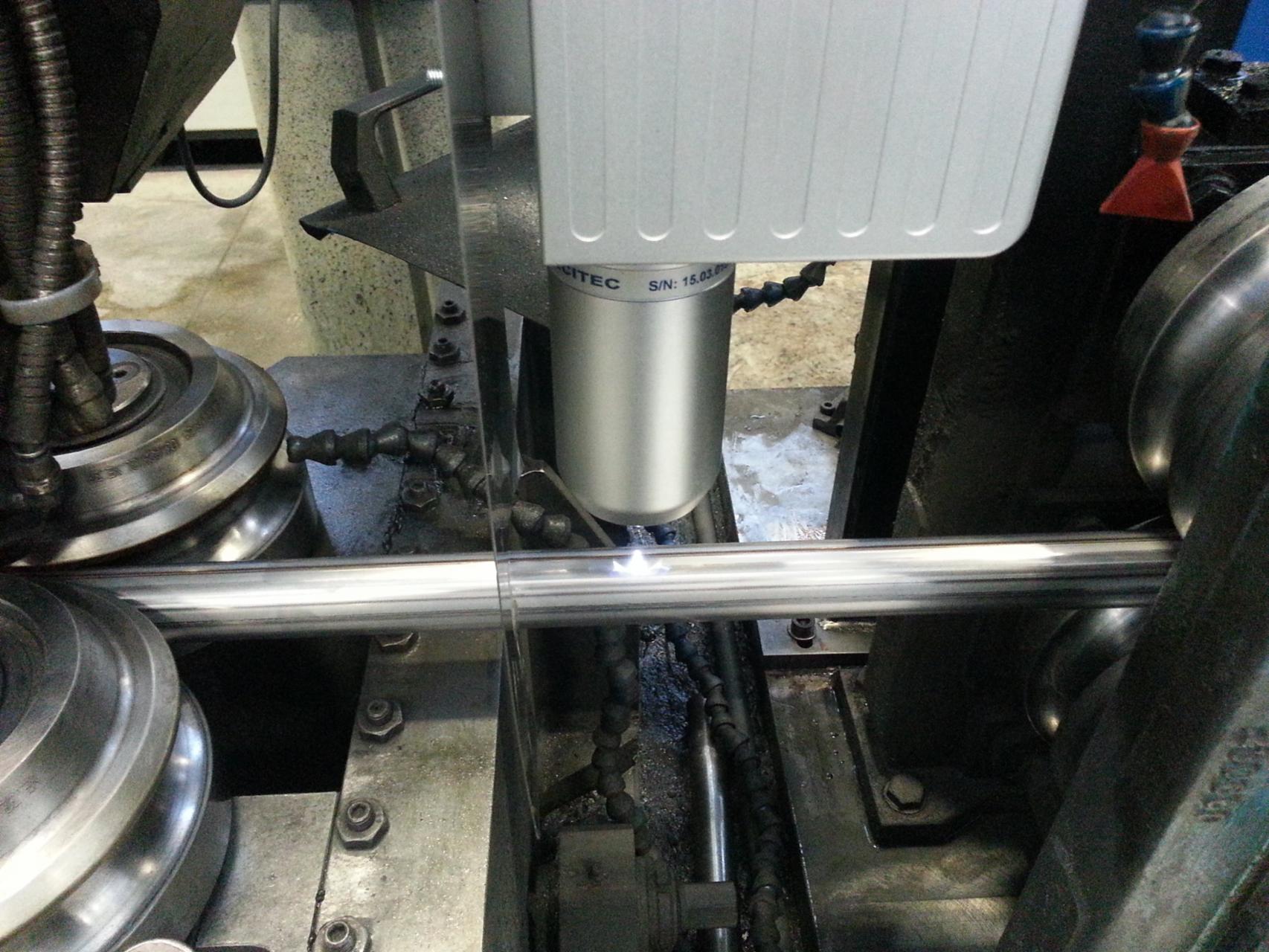

A.B.Esse, after the acquisition of specific skills in the field of the laser cutting and welding and non-contact optical measure applications, picking-up the indications and the requests coming from some customers realized a specific application for the metallic tubes manufacturing in-line control. The idea was born from the intuition to apply an already known resource among the products range but usually dedicated to a different market, typically connected to laboratory measures and for "clean" environment, to check the laser welding process inside the production lines.

The laser welding process is another branch of A.B.Esse activity as said where in the recent time the request of monitoring solution is becoming more and more common and the application of this monitoring devices more and more needed but where only traditional and well-proved technologies found places so far.

WELDING SEAM INSPECTION

TDiM – TUBE DEFECT IN-LINE MONITOR

It's a real-time monitoring system specifically thought and realized on metallic tube production companies needs. It's based on the welding seam dimensional direct measure performed by a non-contact optical white light technology (not a laser). Among the advantages of such a kind of measure there is the possibility to visualize and measure at the same time on a micrometer scale (accuracy ±1µm) the in-line profile of the longitudinal weld performed along the tube/pipe. The system is able to operate even as a real automatic monitoring system and acts without operator control as well to detect and alert possible undesired process irregularities (like micro-holes, edges misalignment or missing weld beyond the set acceptance threshold) that are sent to the line plc while the single events are recorded on an hardware support and are always available for a future and further post-process analysis done using the same software application.